Geomagic Control X

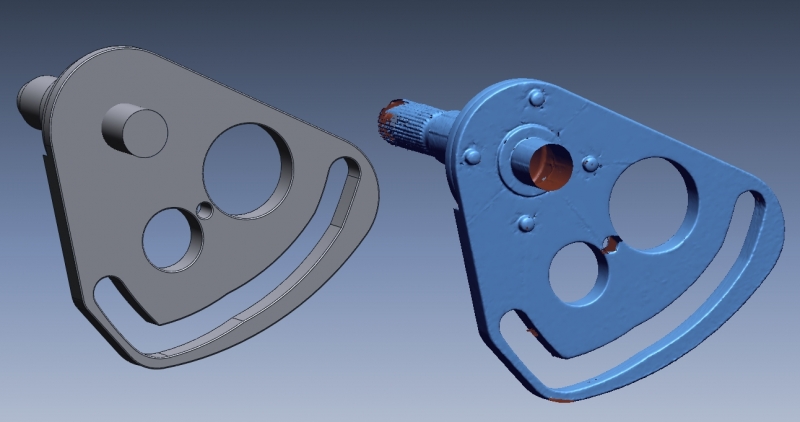

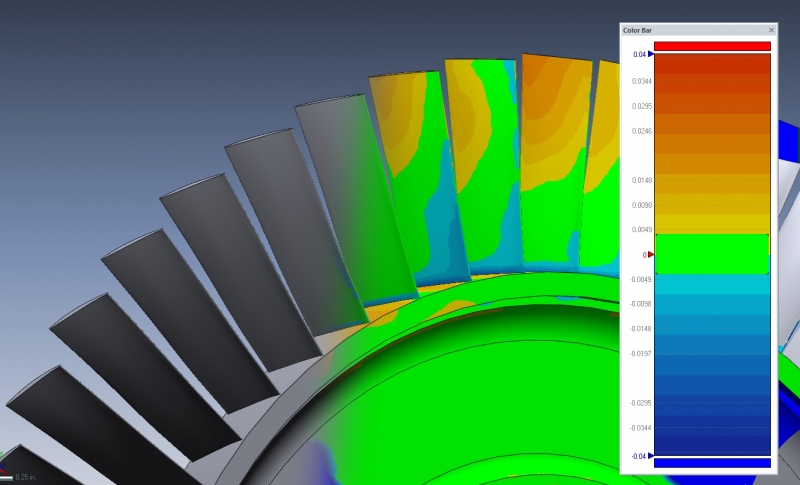

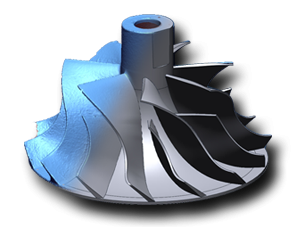

Geomagic Control X is a comprehensive metrology software platform that delivers the industry’s most powerful tools within straightforward workflows. With Geomagic Control X quality managers are enabled with revolutionary ease-of-use, intuitive, comprehensive controls and traceable, repeatable workflows for the quality measurement process. Its fast, precise, information-rich reporting and analysis enable significant productivity and quality gains in any manufacturing workflow. For aerospace and automotive industries, Geomagic Control X 2018 now includes scan processing automation, deviation location and airfoil analysis capabilities.Revolutionize Your Inspection Routines

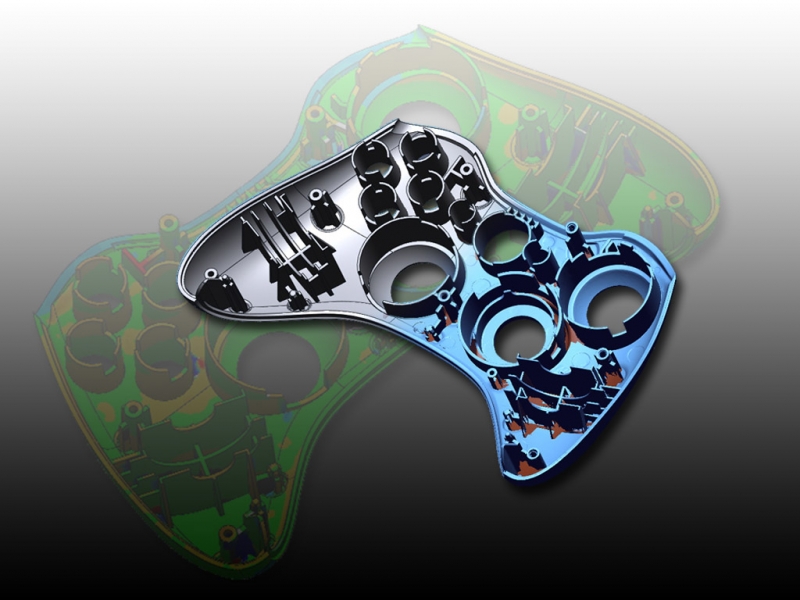

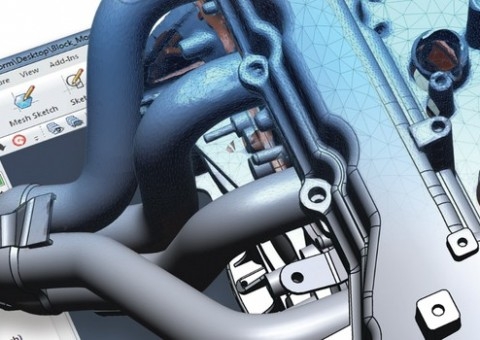

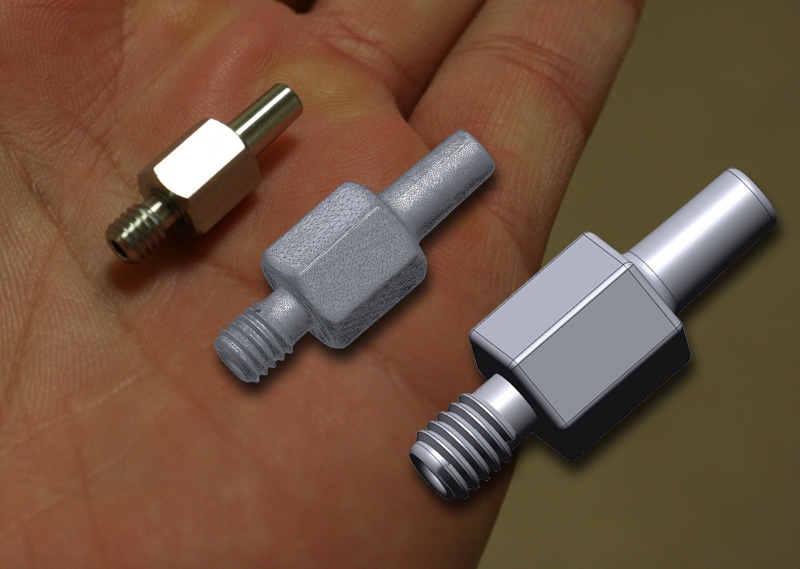

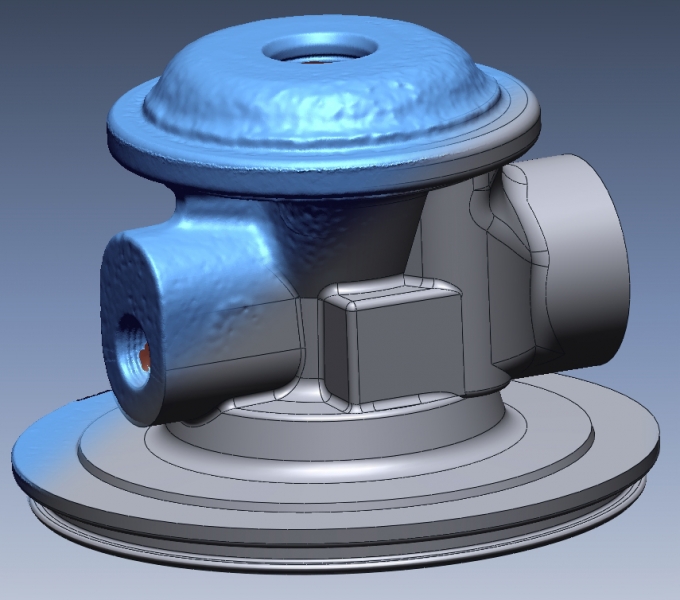

With a new User Interface, innovative new metrology and inspection tools, workflow-driven, preplanned processes and casual walk-up inspection, and more, Geomagic Control X delivers an unparalleled ease-of-use and comprehension for 3D inspection in any manufacturing workflow. Now accurate measurement and fast analysis of manufactured parts and assemblies are on-hand for anyone looking to significantly build quality in manufactured parts and assemblies.The Power to Get Reliable Results. The Simplicity to Get Them Quickly.

Have the freedom to measure in any order or style you desire, while the powerful Synchronous Inspection system captures the data hierarchy and automation in the background for repeatable and editable processes. Focus on getting the results, not wasting time worrying about how to make the software work for you. Quickly conduct First Article inspections using the CAD-based dimensioning tools and have communication-ready information instantly at your fingertips. Native CAD importers including those which contain model-based GD&T definition are delivered standard at no additional cost.Immediately Understand Your Inspection Results

Improve your ability to investigate quality issues that may appear across parts or over time through the multiple results system and Result Navigator. Identify the sources of stack-up error in weldments or assemblies by simultaneously working with many results, and derive meaningful, actionable information from the analysis. Understand potential assembled part-related issues, using portable measuring devices, optical scanners and even computed tomography by collecting families of parts or an assembly into one inspection project for easy cross part referencing. Maintain a single project for a single part which contains all measurements over time, and graphically investigate cross supplier issues.Communicate the Right Data to All Stakeholders

New powerful reporting features in Geomagic Control X enable graphically-rich, communicative reports. Custom viewpoint control and view-style reporting empower you to make your report more closely follow a traditional paper or pdf print graphical presentation. Brand new, intelligent 3D dimensioning and annotation management processes enable you to control in fine detail how dimensions will be displayed. You can pick from some popular default representations or create personalized and customized annotation styles to match your company standard. New, advanced report layout tools give you the flexibility to choose how reports will be configured, in the format you prefer.Experience Total Accountability and Tracebility Through All Inspection Workflows

NIST-PTB certified results give you the confidence to inspect rapidly with accuracy. The new features of Geomagic Control X allow you to build inspections with total accountability and traceability throughout the entire process.VideosFeaturesBenefitsData Sheets