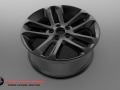

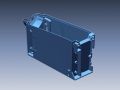

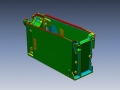

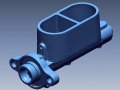

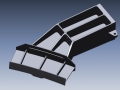

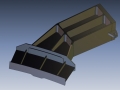

Reverse Engineering

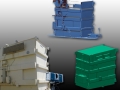

EMS's reverse engineering services team can quickly 3d scan small parts or large objects on or off-site to create CAD for prototypes and legacy parts.In the world of 3D scanning, reverse engineering is the process of taking an existing physical object and creating a 3D CAD model. The advantage of using a 3D scanner for this process is that it is much more accurate and faster than any manual measurement methods for complex parts. A basic rule of thumb is that if it’s difficult to measure using manual methods such as scales, tape measures, calipers and gauges then 3D scanning is the best method to use.

Benefits of 3D Scanning for Reverse Engineering

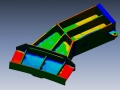

- Very accurate method of capturing a physical part – up to 15 micron (.015mm /.00059”) accuracy

- Capture complex and organic shapes quickly

- Non-contact methods ensure accuracy and integrity of the data captured.

- Much faster method of generating surface and solid models

- Modify an existing design from 3D Scan data

- Design parts to fit up to or integrate with an existing object

- Capture very small details – down to 16 micron (.016mm / .0006”) point spacing

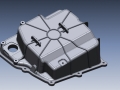

Reverse engineering deliverables

- Point cloud data – color or non-color – PTS, PTX, XYZ

- Polygon models – STL, PLY, OBJ, VRML

- 3D Surface model –IGES, STEP

- Feature based solid model & assemblies – IGES, STEP, ParaSolid, SolidWorks

- Hybrid CAD model (surfaces and solids) – IGES, STEP, ParaSolid, SolidWorks

- Photo realistic renderings

- Drawings

- Animations