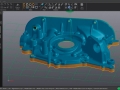

Real-time visualization - the user can view the 3D surface as the object is being scanned

Surface optimization algorithm - avoids the creation of multiple scan layers and ensures a more accurate mesh without any post-treatment;

Direct mesh output - an optimized mesh can be exported in all standard formats, right as you complete acquisition. No complicated alignment or point cloud processing needed;

No limitation to the scan resolution - you simply need to input a resolution value, independent from the size of the scanned object. Resolution can be changed at any time before/after the scan;

User-friendly interface - VXscan was designed to simplify the whole scanning process to its essential core, through a powerful and simple process

Scan results enhancement - hole filling, smart decimation, boundary filters, etc

Alignment tools - highly flexible, you can simply constraint your scan using datums/entities.

NURBS Surfaces - easily generate NURBS surfaces for characterizing freeform surfaces for later use in your CAD software

Mesh Improvement - modify the 3D scan mesh, make it watertight

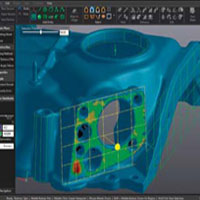

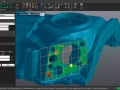

Mesh comparison - enables you to calculate both mesh-to-CAD and mesh-to-mesh deviations.

Geometrical entities & Cross-sections - Use your 3D scan as a reference for your design.

CAD import - Use your 3D scan as a reference for your design.

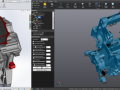

Multiple-Measurement mode - first software to seamlessly integrate both single-point touch probe and non-contact measurements into a unique and intuitive software interface.

Alignment - ensures more accurate results from data acquisition up to the final inspection report.

GD&T - sophisticated algorithms and calculation methods offer an accessible way to apply GD&T principles and practices to the inspection project.