It seems that technology for 3D printing services is moving forwards in two directions. At the high end printers are able to print in an increasing number of materials and 3D printing services to print electronics and working parts are now possible where different materials are used so that finished items can be created. Multicolor printing is also now possible so almost any item can now be made ready to use with a high-end 3D printing service.

At the other end of the market it seems 3D printers for home use are becoming smaller and cheaper making 3D printing at home practical. Most of these printers though can only work with one material at a time that is a basic plastic. This limits what can be printed by people at home, it also means that small businesses offering 3D printing services will be limited on what they can offer to customers.

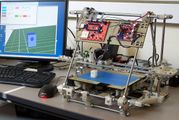

A new design for a home 3D printer called the RepRap was recently unveiled: the designs for it are open source and parts should cost only around £500 which is around $830. This printer though is not only cheap to make but also cheap to run, the printer’s creator Dr Bowyer from the University of Bath says that the plastic used as a raw material only costs around £30 that’s $50, per kilogram, much cheaper than inks then.

An example Dr Bowyer himself gave of a 3D Printing Service that could be performed with these printers was cutting your own key, though he did admit they would only last a week or so. This is the problem with this technology then these cheap plastic only printers will not be able to produce parts that will go through various stresses and strains. These printers may be ideal for printing models and pieces of art but not for making everyday usable objects it seems.

At some point though it has to be presumed that the technology making 3D printing and printers cheaper at the low end will start to make high end printers cheaper to make and run as well which can make a much wider range of items.

Perhaps the multicolor process will be the first to be added to low end home 3D printers which would increase their uses for making models. This would also see them used by small 3D printing services, serving consumers with models for home use and with small businesses using these printers for prototyping. The current niche rapid prototyping market that uses 3D printing services would probably change then and it would be fully working prototypes they would specialize in and maybe eventually large scale 3D printing services with 3D printing done at much faster speeds and bigger sizes than will be possible on smaller home machines.

Where current rapid prototyping services will also benefit is from their ability to provide 3D scanning services that make 3D printing services far more useful. Otherwise designs have to be made from scratch and the number of graduates with these skills will possibly take some time to catch up with the technology and subsequent demand.

Source: Wall Street Journal